- Our technology

- Construction materials for a prefabricated house

Construction materials for a prefabricated house

At Marles, we pay particular attention to the materials we use in our buildings, as we want to maximise the living environment for the users of our buildings while minimising the impact on the environment.

For this reason, we use only materials of natural origin in our buildings, with the largest share by far being used for the building's structural elements and insulation materials.

Wood

In Marles houses, wood is the main construction material, used for walls, ceilings, roof beams, windows, doors, and cladding. The use of wood is ecologically acceptable as carbon dioxide is sequestered from the air during tree growth, helping to maintain the natural balance. Marles uses local wood from sustainable forests, reducing transport routes and supporting local forest owners. We only import certain glued laminated wooden products that we do not manufacture ourselves for technological reasons and we source them from European reputable suppliers. Wood is healthy, natural, warm, breathable, does not emit harmful substances and is the only renewable building material.

Gypsum fibreboard

Gypsum fibreboards are used for the construction of Marles houses, providing structural support and levelling of the walls. They are fire-resistant, water-repellent, provide good acoustic insulation and are a good regulator of room humidity. Gypsum fibre boards are made entirely of natural materials, namely gypsum and cellulose fibres obtained by mechanically shredding selected types of waste paper.

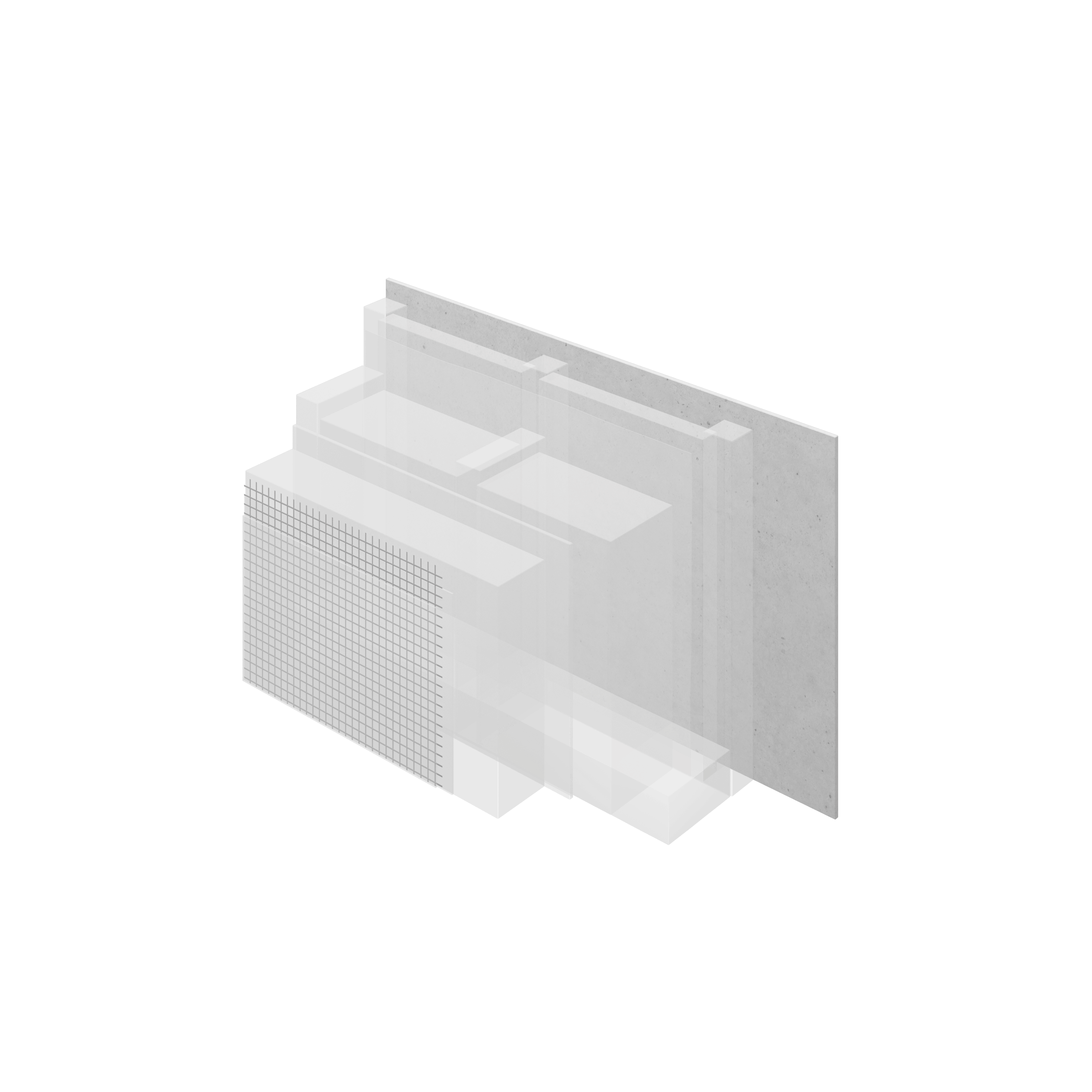

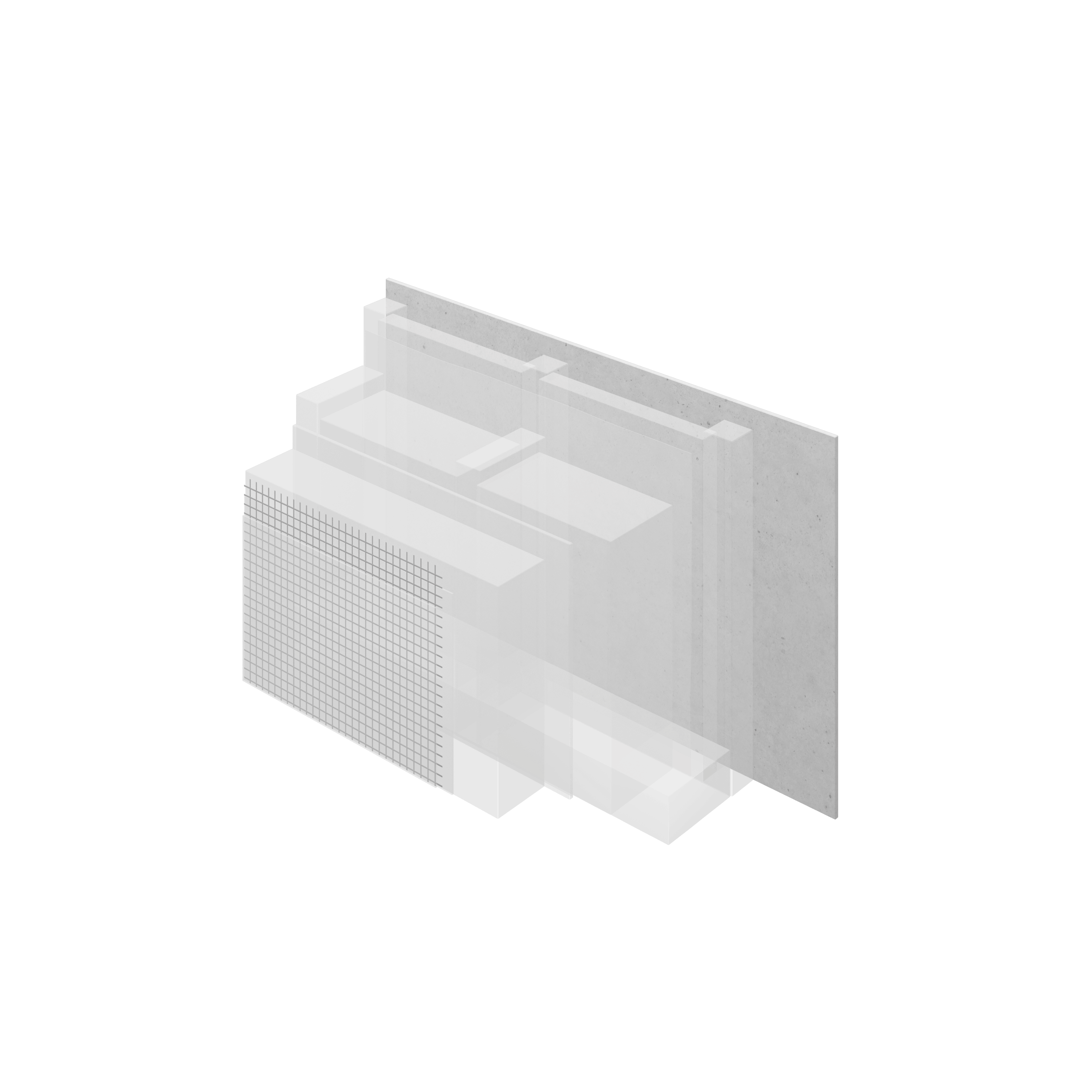

Neopor

Expanded polystyrene rigid foam thermal insulation board with the best thermal insulation performance on the market.

Neopor is a new, highly efficient thermal insulation material based on expanded polystyrene - Styrofoam. Neopor is characterised by its high thermal insulating properties due to the addition of microscopically small graphite particles. It allows thinner insulation boards with the same performance and is mainly used for façade insulation.

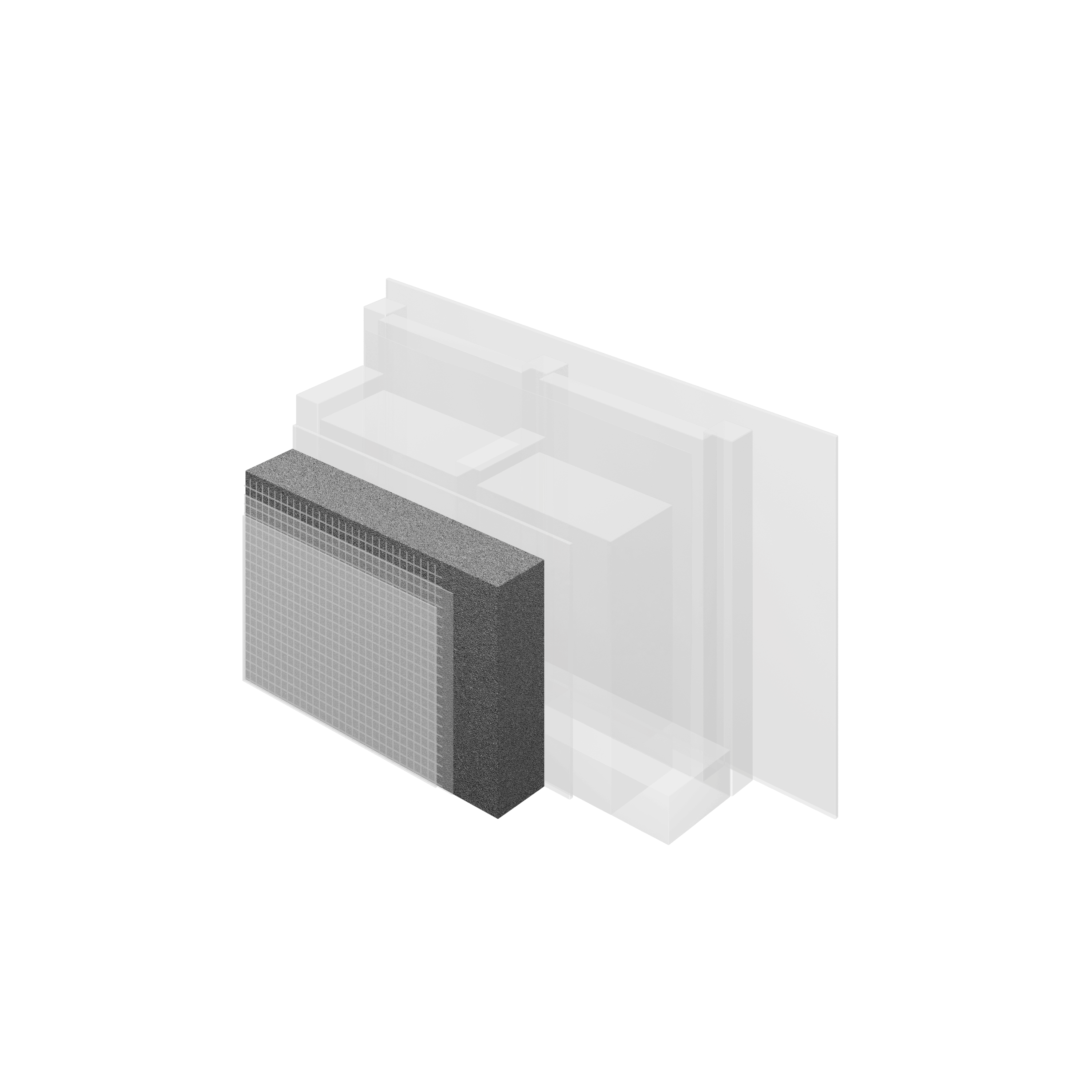

Rock mineral wool

Rock mineral wool is the most used insulation material in Marles houses, used to insulate external and internal walls, floors and the roof. Rock mineral wool is the ideal choice due to its insulating properties, fire resistance and environmental friendliness.

Rock mineral wool is manufactured in different shapes, dimensions, and densities, and is therefore suitable for insulating all parts of new buildings. It is used for external wall insulation in the form of panels and slats. The production process, especially for facade panels, has been adapted to meet the requirements of the increasing thickness of thermal insulation, which means that they have a higher tensile strength.

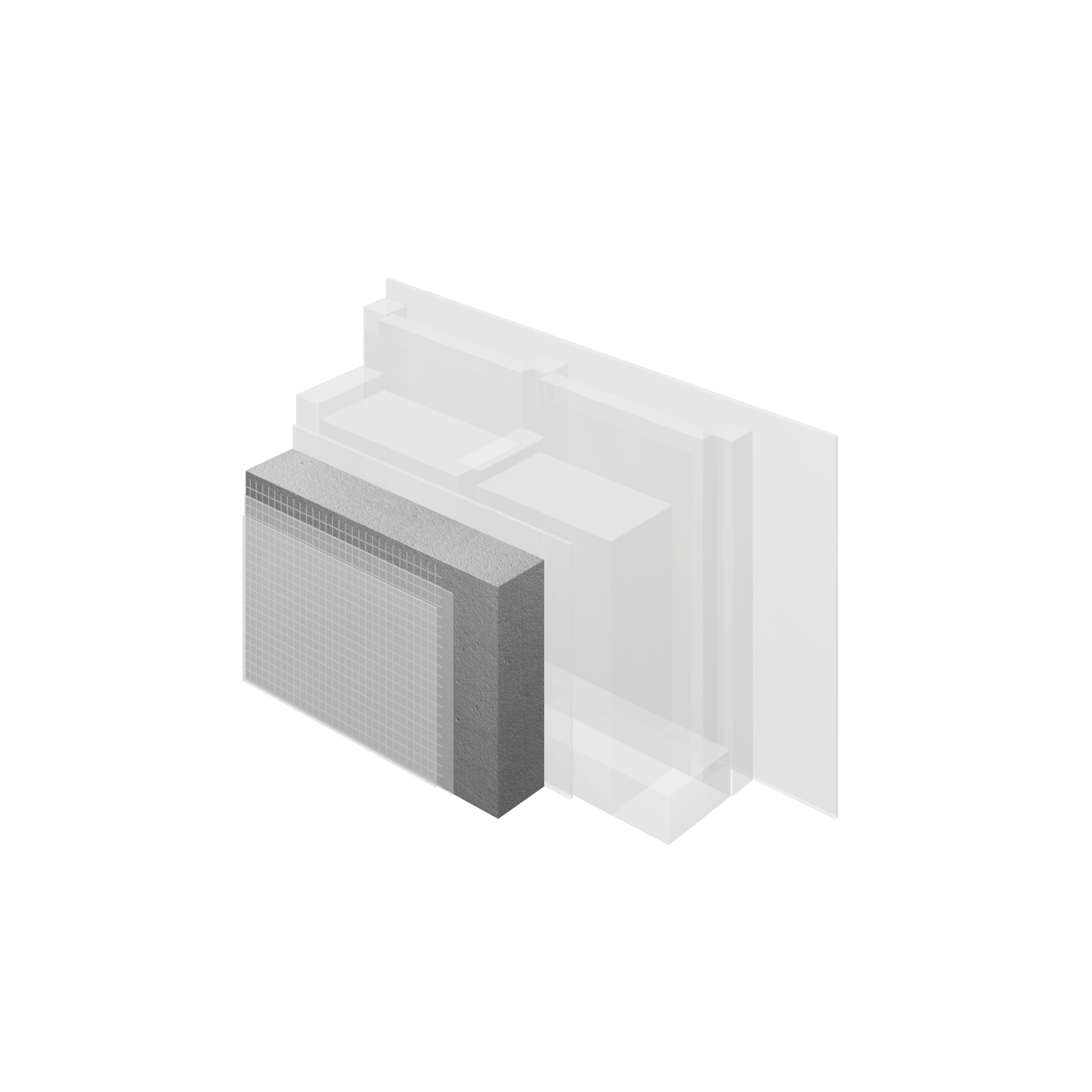

EPS

Façade insulation made of EPS boards provides the best thermal envelope for the building, with no additional compromises. All façades of MARLES buildings are made in the system of STO as the supplier for the best quality and durability of the façade layers.

Cellulose

Cellulose insulation made from recycled newspaper is used to insulate walls, roofs, and wooden ceilings. Cellulose is environmentally friendly, does not cause itching or allergies and acts as a regulator of room humidity. At the same time, it is the only insulation material that is produced through recycling, so it does not require new raw materials from nature.

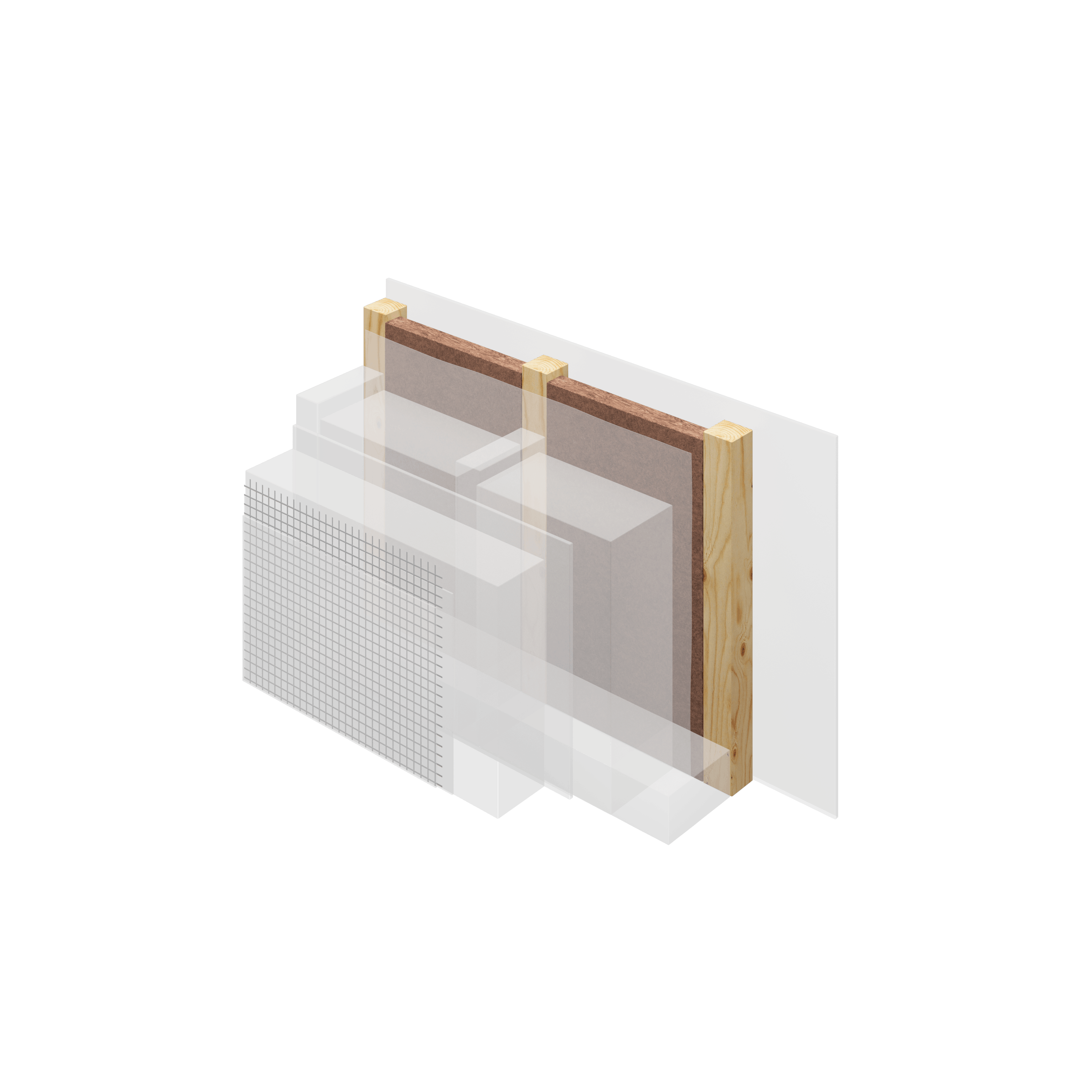

Wood fibre thermal insulation boards

Wood fibre thermal insulation boards are used in the Marles EKO systems. It is a natural material made from fresh wood obtained through thinning of forests, which ensures the well-being and quality of living in the house. Another positive feature of wood fibre insulation is that it does not emit toxic fumes in the event of a fire.

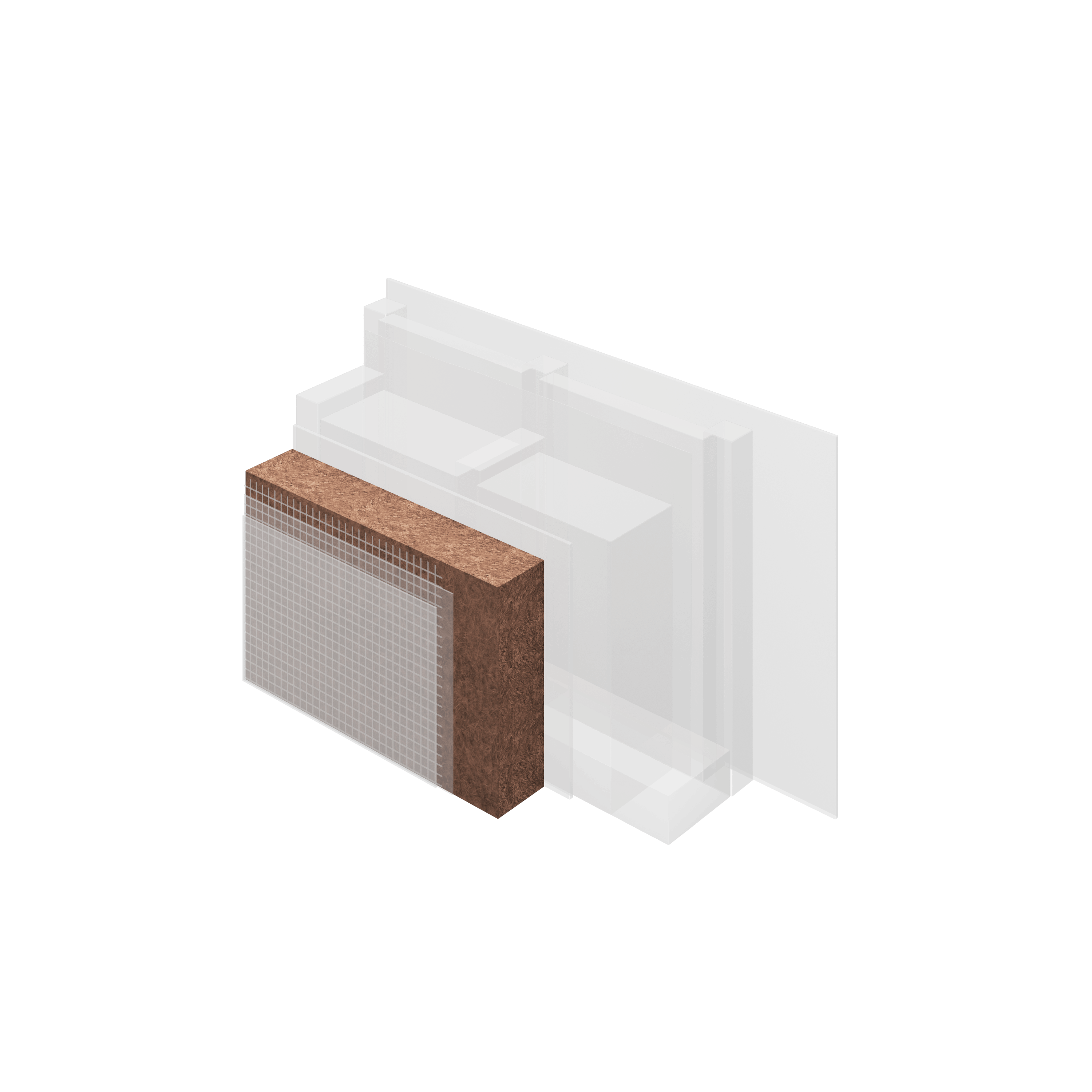

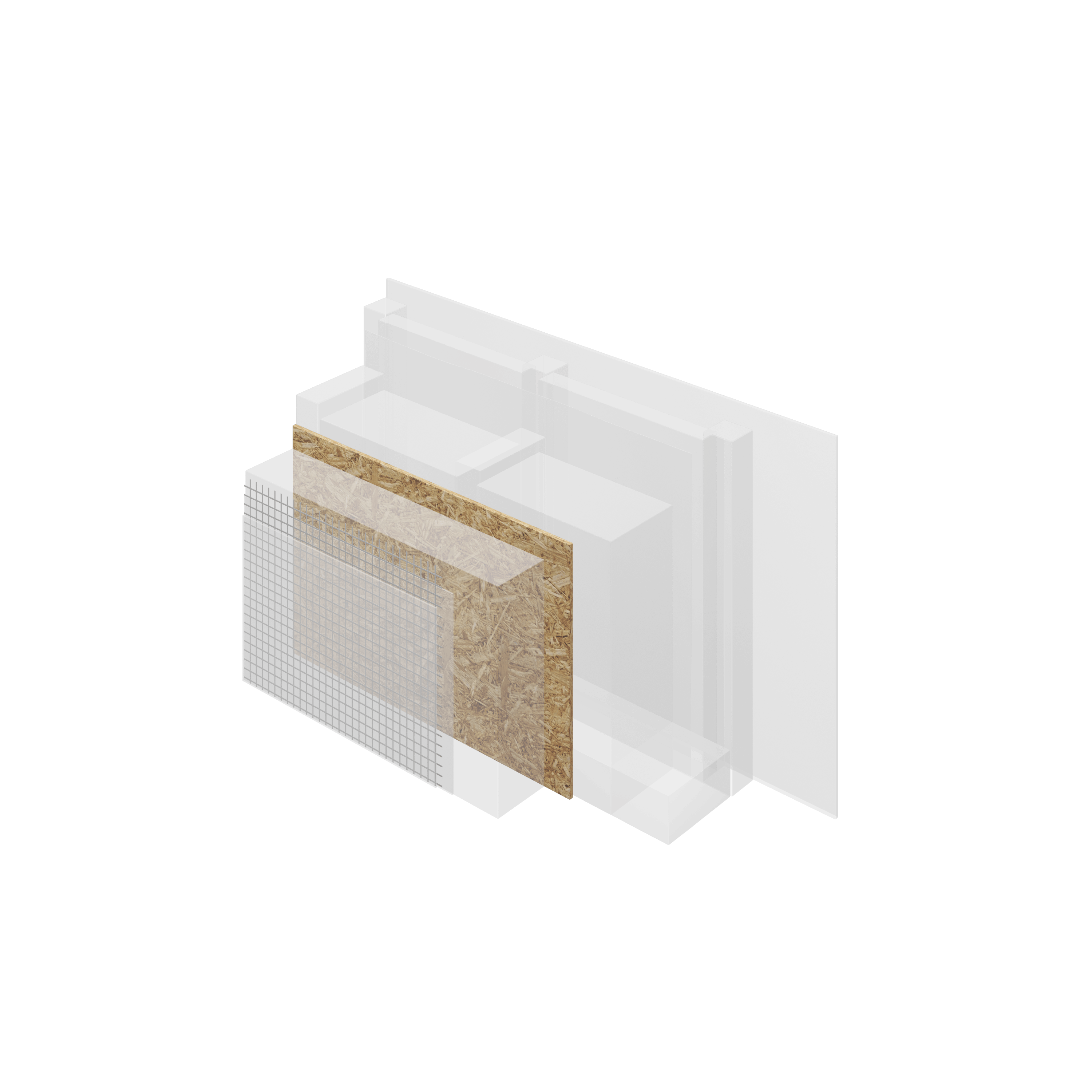

Façade insulation wooden fibreboards

Wooden fibreboard insulation façade panels are used in the EKO and some of the NATURA systems. They are water-repellent, highly diffusive and provide excellent thermal insulation both for the summer and the winter. In addition, the panels also have a high material density, which represents outstanding insulation properties.