The lens of time confirms: Marles solutions grow alongside generations

Exactly 50 years ago, Marles completed one of the most important projects of its time – the construction of a neighborhood with 136 prefabricated houses in Tezno. The houses were designed with rationality and technical precision, tailored to the living conditions and social needs of that era.

Standardization enabled faster construction, better energy efficiency compared to traditional building methods, and long-term sustainability—proven by the fact that many of these homes are still serving their purpose with quality today.

1975

2024

Over the decades, it wasn’t just technology that evolved – people did too

Today’s lifestyle demands more light, open floor plans, flexible spaces, and the expression of personal identity. At Marles, we no longer speak only of building houses, but of creating homes that adapt to each individual. We continue a tradition built on more than 125 years of experience, enhancing it with advanced technology, architecture, and a commitment to sustainable development.

Now, 50 years later, we proudly carry on this tradition—interwoven with innovation, high quality, and dedication to a sustainable future. In this time, we have built several residential neighborhoods across Slovenia, as shown in the images below.

From small-panel to large-panel systems - all the way to assembly in just two days

In cases like the construction of 136 houses in Tezno, Maribor, we used the so-called large-panel system. This meant that we produced basic—raw—wall elements in the factory without built-in windows, doors, shading systems, or final facade layers. These elements were then transported to the construction site, where much of the work had to be completed manually. All additions and finishes had to be installed on-site, which extended the construction time and reduced the possibility of complete quality control during execution.

Today, we operate on an entirely different technological level. In the production process, wall elements are prepared to such an extent that they already include built-in windows, entrance doors, shading systems, facade layers, and window sills. This significantly shortens assembly time while eliminating the need for additional construction work and keeping the construction site as organized as possible. This means lower costs, less noise, reduced stress, and—most importantly—fewer chances for inconsistencies.

When such an element arrives on-site, it only needs to be installed—without any further construction work.

The evolution of quality and energy efficiency

As early as the 1960s, Marles was already implementing advanced solutions for that time: walls with 10 cm of insulation, ventilated facades, and facing brick. Even then, we exceeded the thermal performance of traditionally built houses. But our development did not stop there.

Today, our walls are more than three times as thermally efficient. We use multi-layered constructions with advanced materials that retain heat in the winter and prevent overheating in the summer. In addition, our systems can be adapted to the microclimate, altitude, and orientation of each building—tailored to the specific conditions of your location.

“In addition, modern prefabricated construction has another key advantage: thermal phase shift. This is the amount of time it takes for heat to pass through the wall into the interior. In the past, it was 6 hours—meaning homes would quickly overheat in the summer. Today, this time is at least 12 hours, which means indoor spaces remain comfortably cool even during prolonged heat. We achieve this by incorporating environmentally safe materials that are non-polluting and eco-friendly.”

– Toni Šauperl (Head of Technology Development and Quality)

A high-performance building envelope acts as a natural barrier against temperature fluctuations, creating a sense of stability, safety, and comfort. Simply put: less heating in winter, less cooling in summer. Lower monthly energy bills. Reduced dependency on energy sources and greater cost stability in the future. And what residents notice most—your home will always feel pleasant, with no drafts or the sensation of "cold walls." This has significantly improved the overall comfort of living in our homes.

The thermal transmittance of windows we used to install was around 3 W/m²K. Today, our windows achieve a value as low as 0.9 W/m²K. This means that hardly any heat escapes through the glass or window frame.

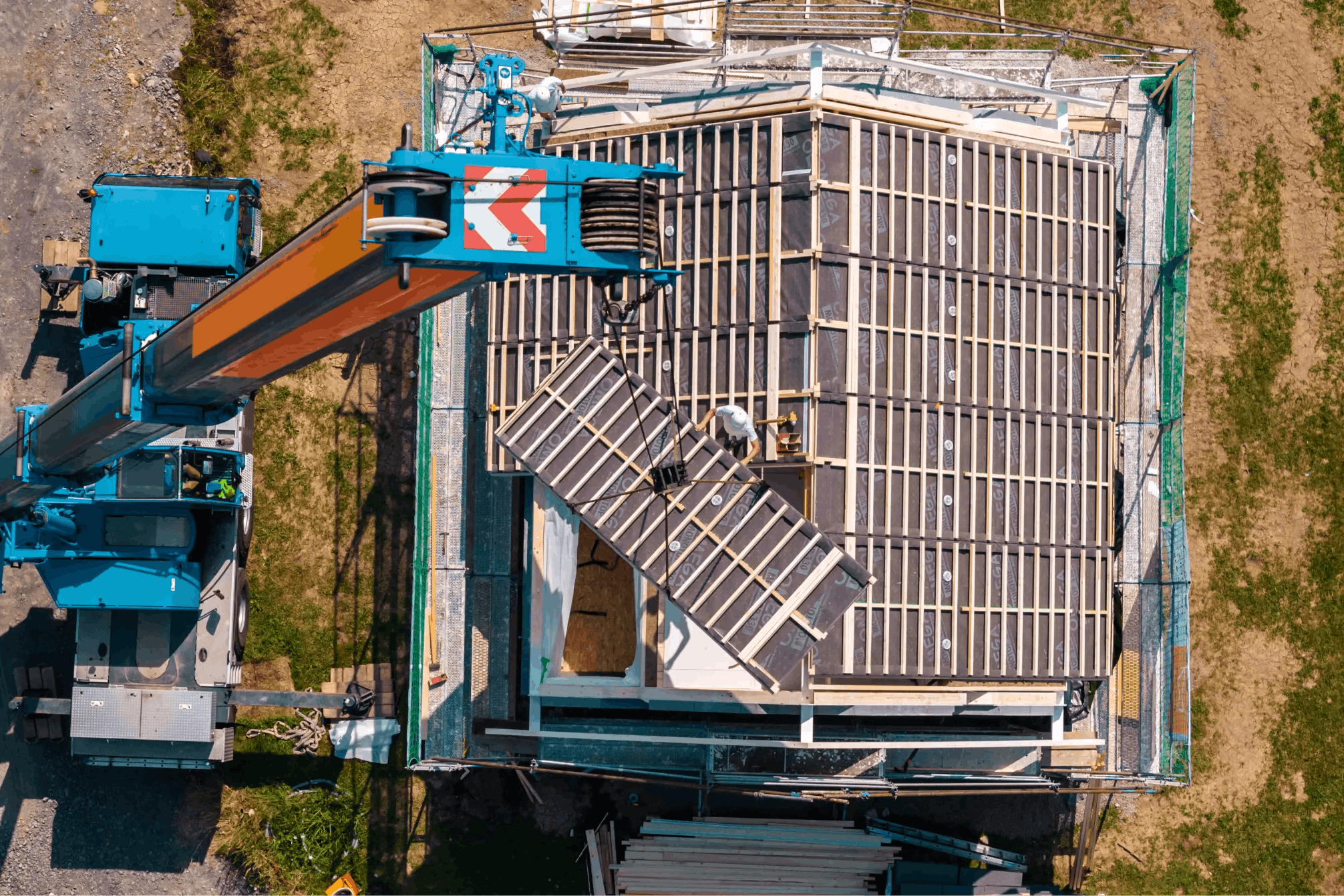

From rafter roof structures to Marles roof elements

In the past, we relied exclusively on rafter roof structures for roof installation. Today, we use advanced roof elements that enable faster assembly, higher thermal efficiency, and greater architectural freedom.

From standard solutions to complete individualization

In the past, prefabricated construction was based on standard solutions. Architecture was limited by materials and structural possibilities, resulting in smaller houses with narrow spaces and shorter spans between walls. The technology at the time simply did not allow for open floor plans or greater architectural freedom.

Today, we are capable of much more. Our structural systems allow spans of up to 10 meters—without intermediate supports. This means we can create spacious living rooms, kitchens with islands, galleries, large glazed surfaces, or living areas that breathe with light and nature.

Standard homes were once the best choice—given the limited range of materials, available technologies, and user needs, they offered a fast and efficient solution. Today, as lifestyles have evolved, Marles offers both: modern, pre-designed homes optimized for quick construction and easy placement on various plots, as well as fully customized projects—either in collaboration with an external architect or as a comprehensive solution developed within our own architectural studio.

Every solution is tailored to the individual’s lifestyle, space, and wishes. This way, everyone can find a home that truly fits—whether they’re looking for a trusted design or something entirely unique.

“One of Marles’s greatest values is our long-term commitment to customers. Our story doesn’t end with the handover of the house. We continue to care for our buildings and provide expert technical support throughout their entire lifecycle. To this day, we are contacted by owners of homes built 40 or even 50 years ago. Because we preserve archived plans and technical documentation, we can offer professional guidance during renovations and reconstructions—whether it's energy retrofitting, window and door replacement, or additional insulation. In addition to technical support, we also coordinate contractors for such works. This level of support is rare in the construction industry—but for us, it’s a matter of course.”

– Željko Vene (retired Head of Development Department)

Knowledge built on more than 125 years of experience

Marles holds the longest-standing tradition in prefabricated construction in Slovenia. With over 125 years of experience and more than 30,000 buildings completed, we are pioneers, innovators, and leaders in an industry that doesn’t just build houses—but creates homes: high-quality, durable, energy-efficient, and environmentally friendly.

To this day, we continue to support numerous buildings from the past, demonstrating our long-term responsibility and commitment to our customers.